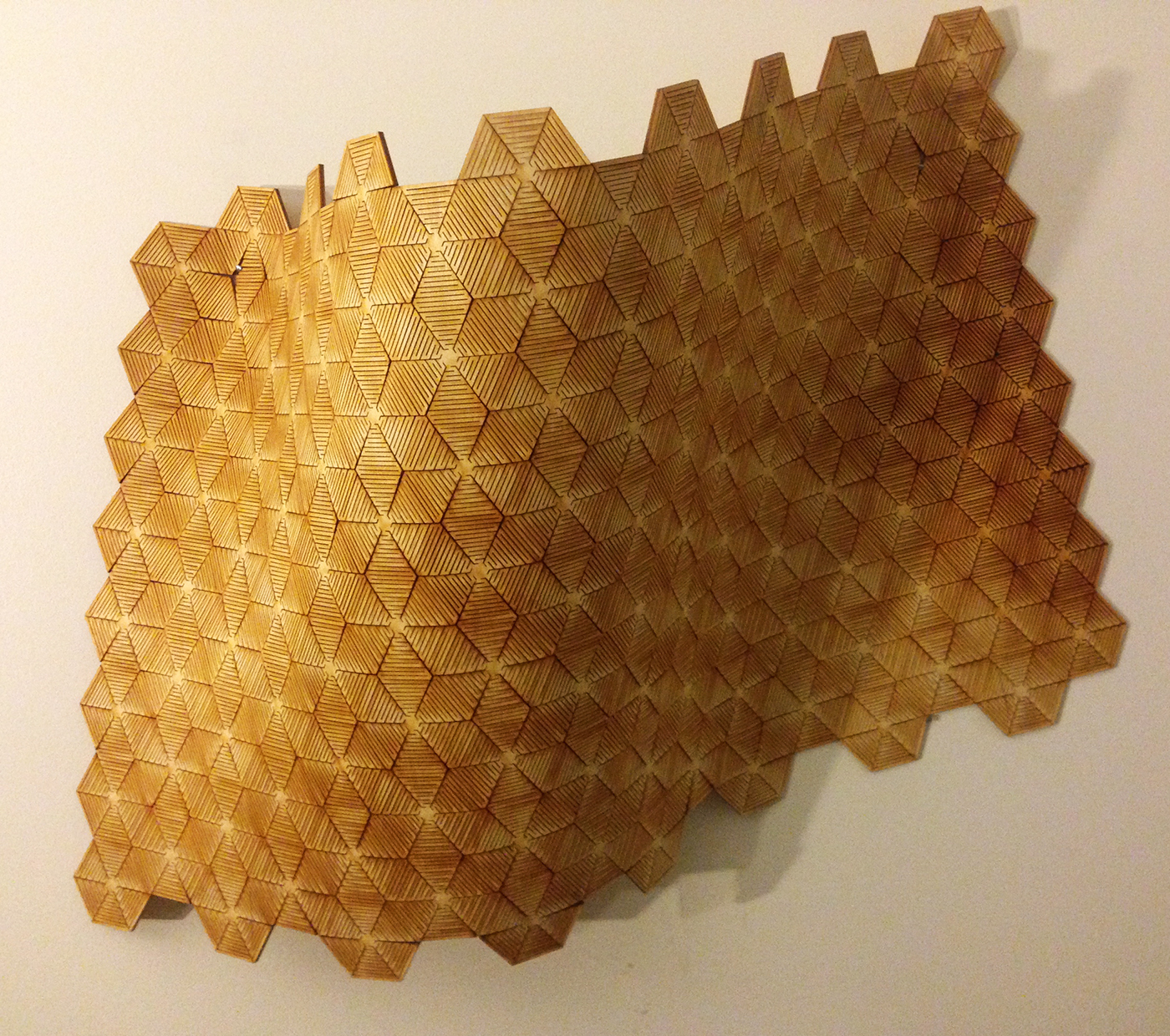

HexaGrid - Lasercut 1/8" Plywood

Using the graphical algorithm editor, Grasshopper, in the 3d modeling program Rhino, I created an easily modifiable methodical cutting pattern to create flexibility from a typically planar material.

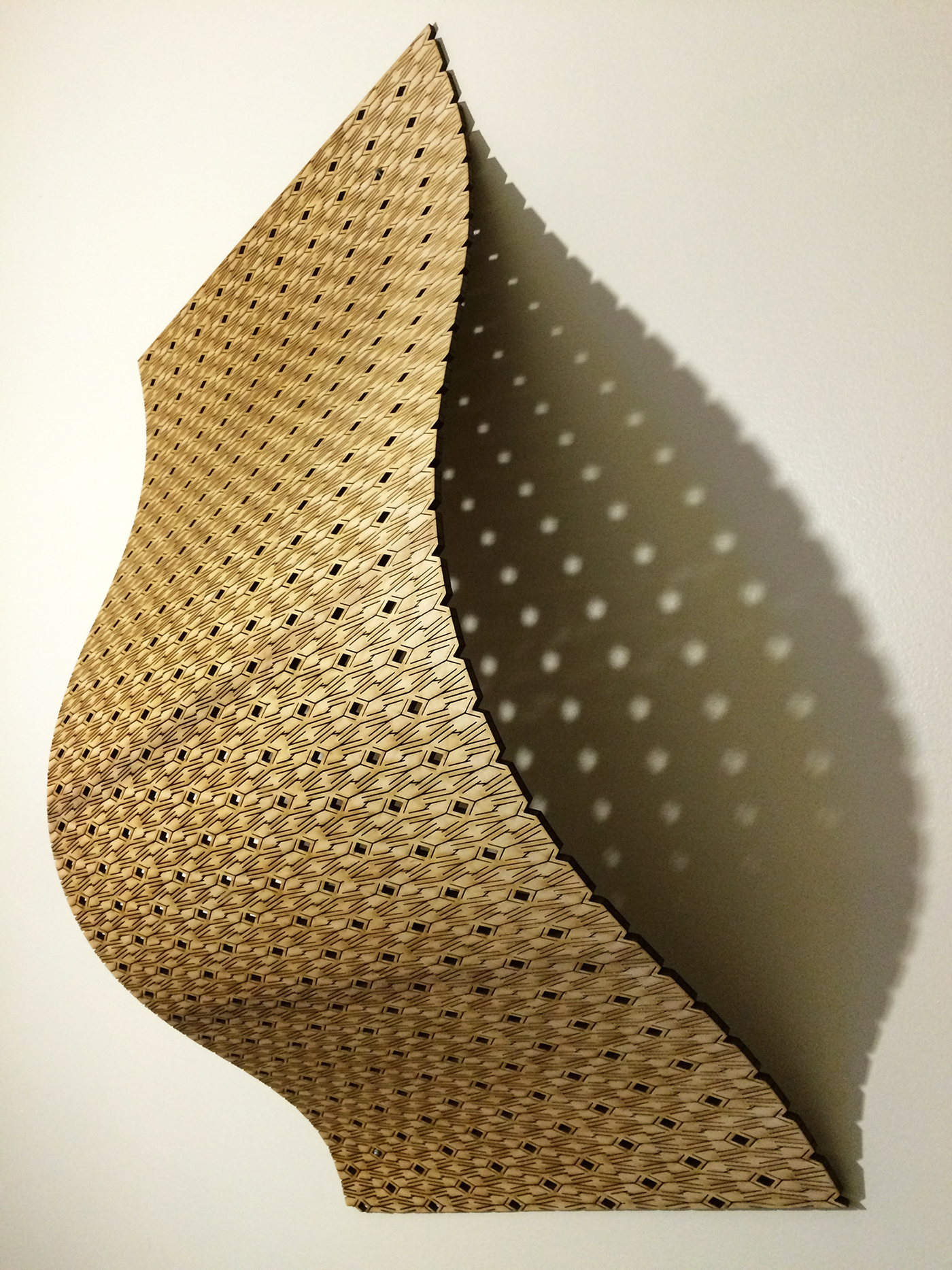

Untitled - Lasercut 1/4" Plywood

After analyzing other living hinge designs, I see the 3d modeling program Rhino, to create a methodical cutting pattern that would allow for one-directional flexibility from a typically planar material. This piece can bend horizontally, but not vertically.

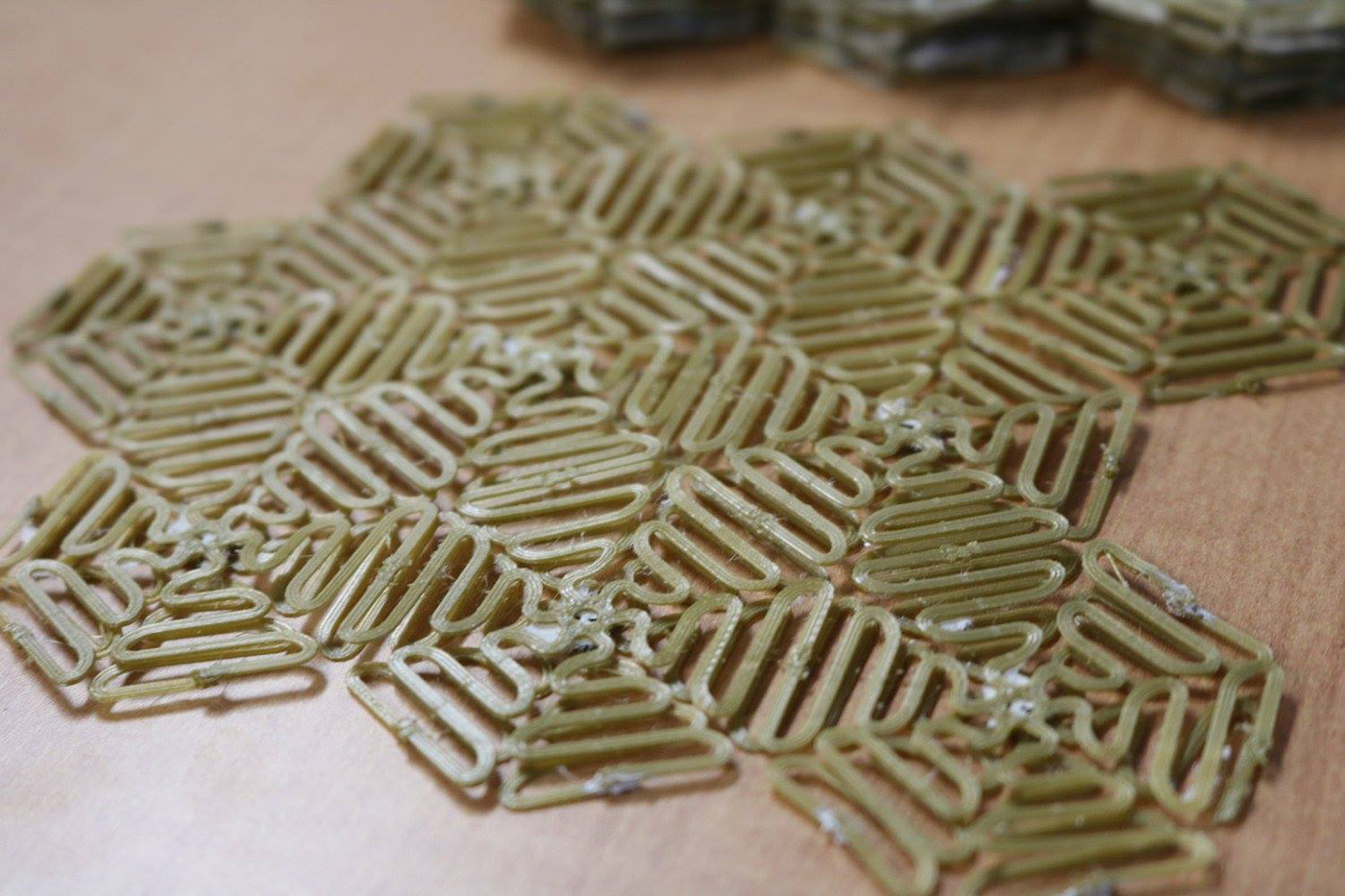

HEMI Prototype- Lasercut 1/8" Plywood, Wire

This prototype was created during a summer internship while working with Johns Hopkins Extreme Material Institute, to be able to visualize and analyze the complex 3d printable design. I had created a multilayered design that could be 3d-printed flat and then expanded into a three-dimensional form. It could also be 3d printed in it's expanded form and would possess a flexibility when compressed.

HEMI 3dPrint - multi-layered PLA 3d Print

This flat-printed design was created by using Rhino, Grasshopper, and Jimmi 3dPrinters in the MICA dFab Lab. I devised a method to print a multi-layered object in which the ends were fused to the next top layer. This creates a flat object that can be expanded to create an enclosed void. Typically the layers of a 3d print fused continuously to create a solid while this piece stretches in both horizontal planes as well as vertically.

Experimental Stretch Sensor - stretchable PLA based 3d print, gold leaf

I experimented with applying gold leaf to PLA to see if I could create a conductive object which could act as a stretch sensor.

Collab Untitled Microscopic Image - Grain of Sand, Microbial Induced Calcium Precipitation, Bacteria Bacillus Pasteurii - Image taken by Kazi Rayhan.

This is a microscopic image from work completed during the Biofabrication based research course Collab, in which myself and three other students, Kazi Rayhan, Emma Whitlock and Mika Rosenberg, worked with Professor Ryan Hoover, to research and experiment with a process called Bio-cementation. We were successful in creating samples of Microbial Induced Calcium Precipitation, in the hopes to devise a method to be able to 3d print this reaction.

Collab Untitled Microscopic Image - Microbial Induced Calcium Precipitation

This is a microscopic image from work completed during the Biofabrication based research course Collab, in which myself and three other students, Kazi Rayhan, Emma Whitlock and Mika Rosenberg, worked with Professor Ryan Hoover, to research and experiment with a process called Bio-cementation. This image shows the Microbial Induced Calcium Precipitate without the bacterial B. Pasteurii and sand. We wanted to see how the reaction occurs in the absence of the bacteria, which acts as the nucleation site, and the sand, which the calcium would attach to.

Balance and Tension- Collaboration work with architecture student Esther Kim. We used an Arduino and servo motors, along with 3d modeled and 3d printed mechanisms to motorized each flexible piece. The viewer would move their hands across a leap motion sensor, which created a virtual plane, and activating the flexible pieces.

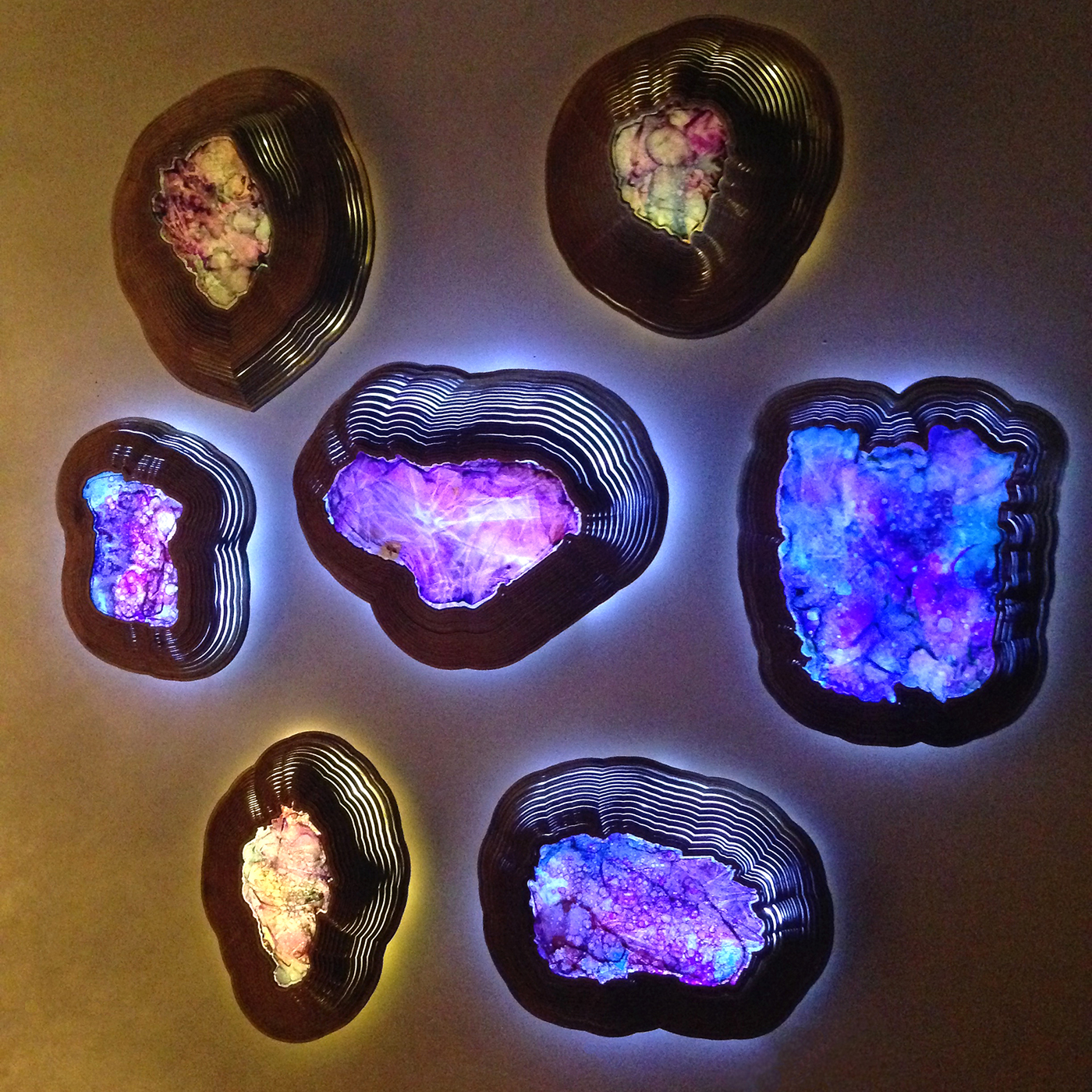

Crystallization Series - inked mylar, laser cut plywood, LED battery operated lighting

Crystallization I - inked mylar, laser cut plywood, LED battery operated lighting