2011 - Nano Comparisons: a collaboration as part of a fellowship with the Institute for Micromanufacturing in Ruston, Louisiana.

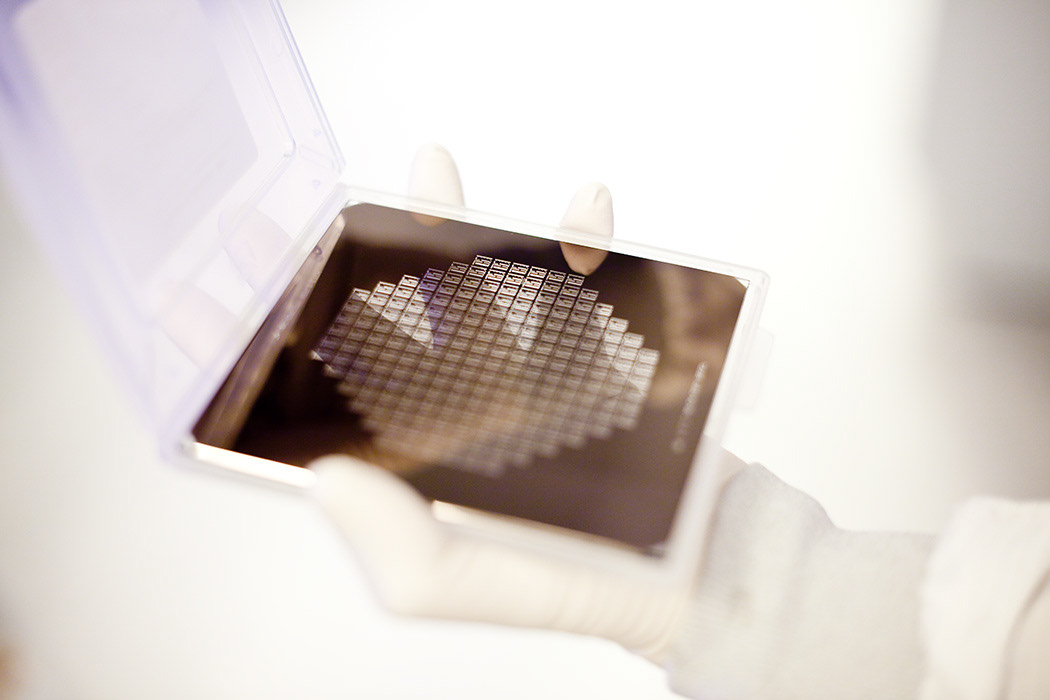

As part of a 2011 Fellowship, I was asked to participate with various researchers and visually respond to the work they are creating at the IfM. One project group I interacted with was Dr. Chad O'Neil's Microelectromechanical Systems (MEMS). These tiny devices are mass produced on silicon wafers using a method not unlike the creation of a photographic plate for lithography, and then diced and parsed out to a variety of devices.

I sought analogies that would depict the device's general characteristics (efficiency & repeatability) that would be humorous and unusual. The way they are designed is similar to a pizza,where every slice is the same. Also a sheet cake. Getting the most servings from a single, uniform creation, that is the premise for pizzas, cakes and MEMS.

As part of a 2011 Fellowship, I was asked to participate with various researchers and visually respond to the work they are creating at the IfM. One project group I interacted with was Dr. Chad O'Neil's Microelectromechanical Systems (MEMS). These tiny devices are mass produced on silicon wafers using a method not unlike the creation of a photographic plate for lithography, and then diced and parsed out to a variety of devices.

I sought analogies that would depict the device's general characteristics (efficiency & repeatability) that would be humorous and unusual. The way they are designed is similar to a pizza,where every slice is the same. Also a sheet cake. Getting the most servings from a single, uniform creation, that is the premise for pizzas, cakes and MEMS.

The mask... or the negative

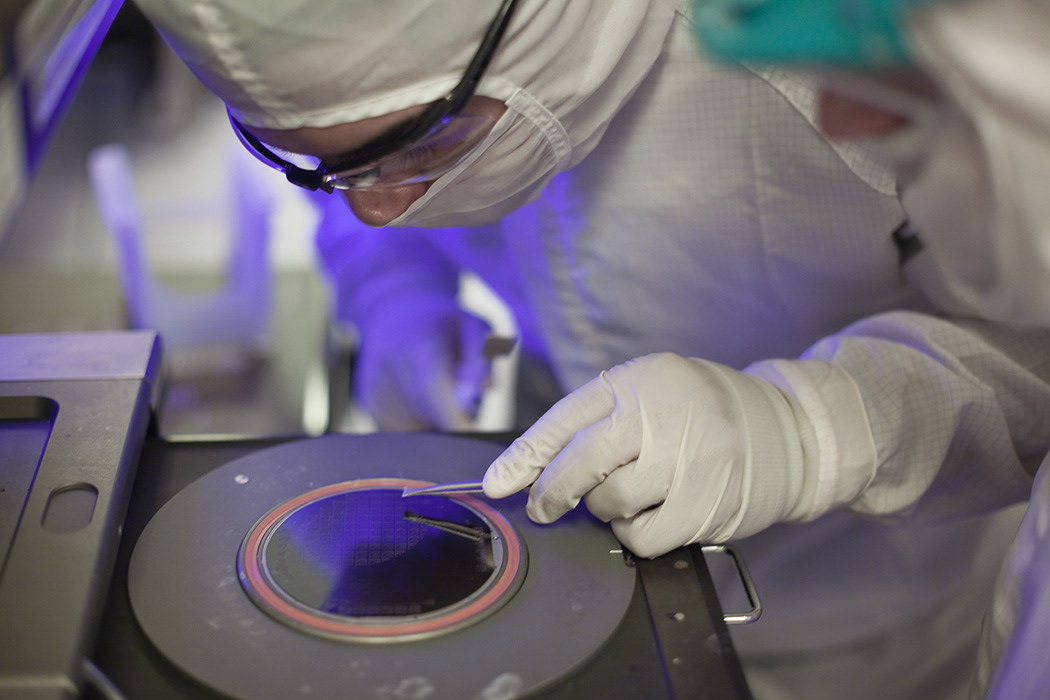

Inspecting the laser pattern

Process of making an efficient pizza device, 44"x60", Archival Inkjet Print

Blueprint for an efficiently engineered cake, 30"x 48", Archival Inkjet Print

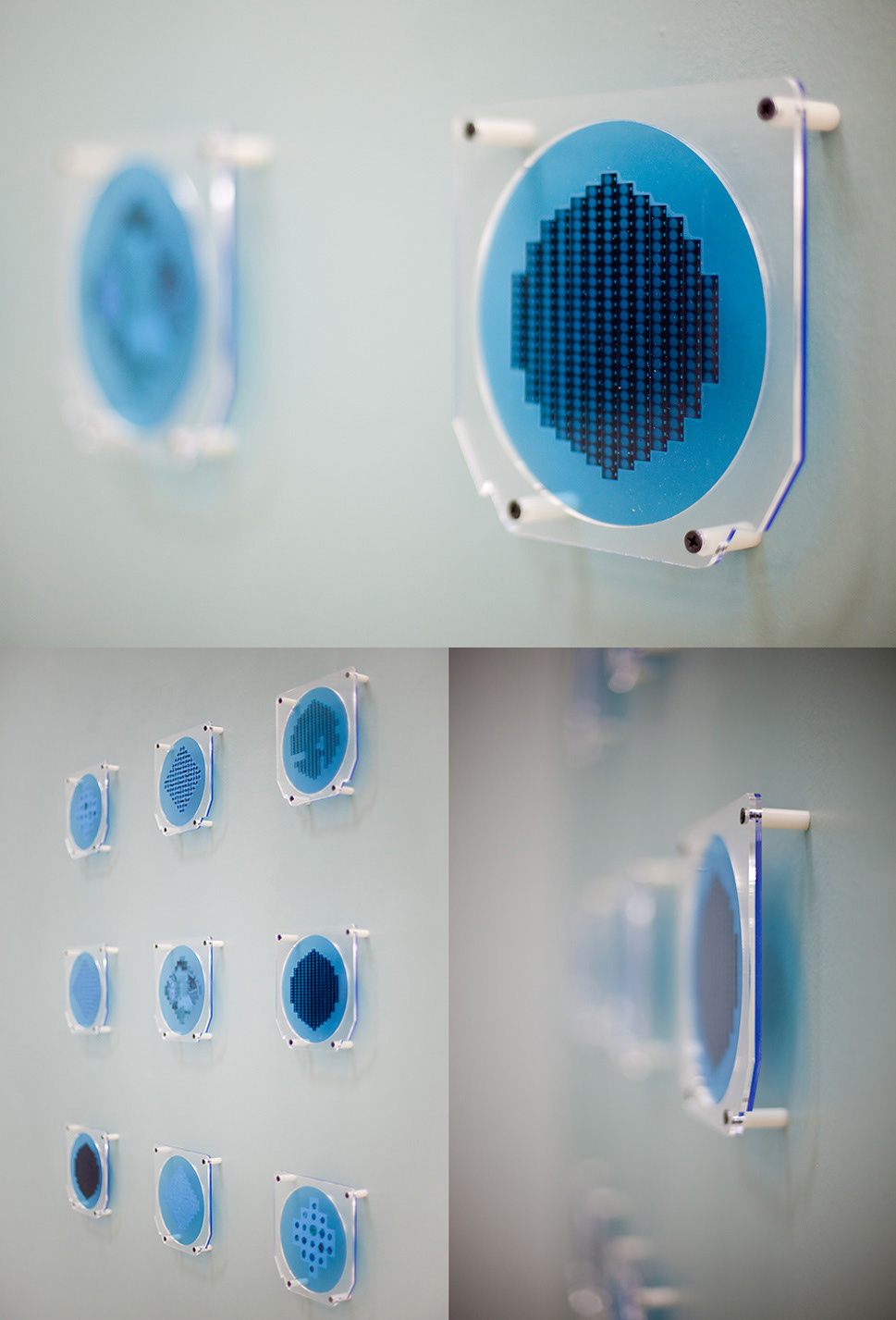

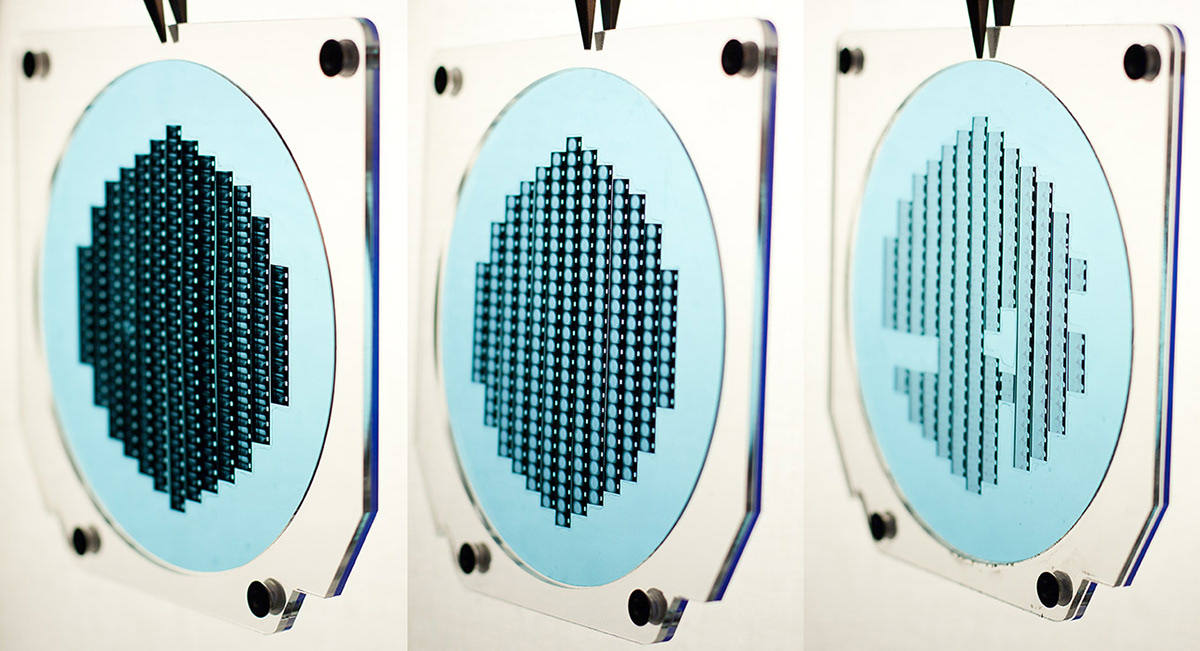

The process for making a MEMS device involves masks (like negatives), photo-sensitive chemicals, lasers, plastics and vinyl. Using these same elements, but in a different way, I created a set of 'wafers' that are similar in form and appearance to a MEMS wafer. Except that my wafers depict the various uses that a MEMS device is intended for. Pressure, temperature, time, acceleration and more are depicted on each frame of the 8mm film - small and intricate, just like the chips they are commenting upon.

MEMS Action Analogies - Lasercut acrylic, 8mm film, vinyl, and hardware